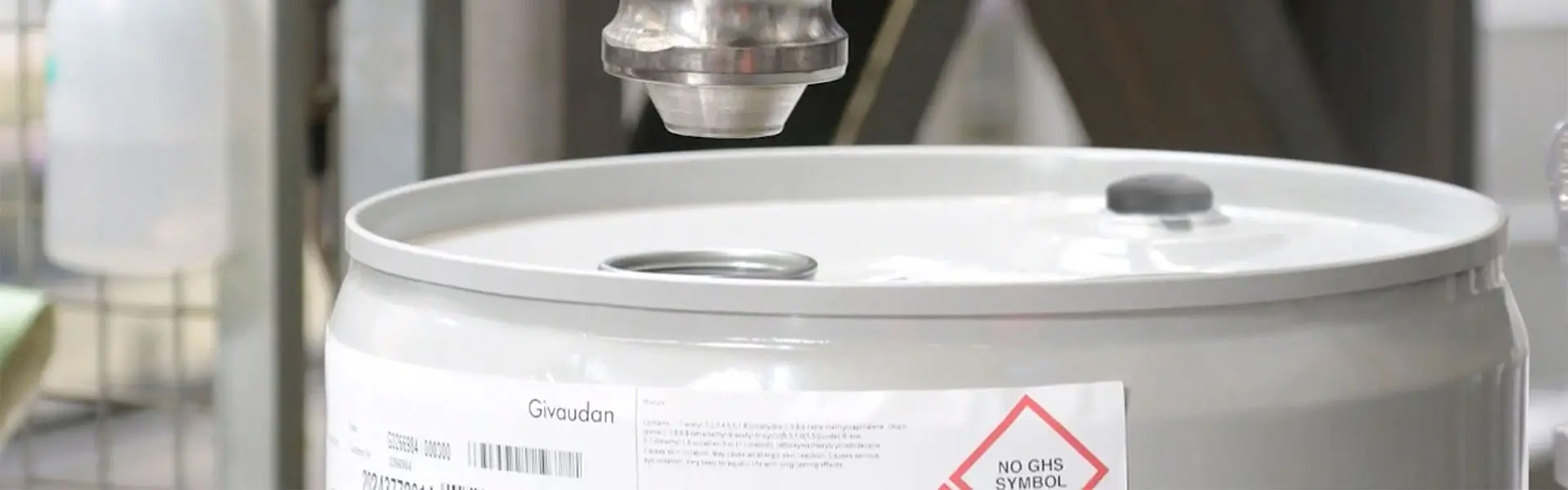

Optimising steel drums globally to reduce our carbon footprint

Packaging is a priority for many companies, including Givaudan, and we are working to reduce its impact on our GHG footprint through multiple approaches.

Within the broader context of our operations, we are driving greater circularity by using more renewable materials, making packaging lighter, optimising it for transport, and exploring reusable and recyclable solutions, all while ensuring safety and regulatory compliance remain top priorities.

One approach has been the optimisation of steel drums used with our fragrance and beauty products. Aiming to reduce both the weight of the drums and the number of different kinds used across sites, we successfully implemented a number of relevant projects starting in 2023. Since then, we have optimised drum specifications through value engineering, and broadened distribution of the improved packaging across sites in NOAM, APAC, LATAM, expanding good practices in this field.

Qualification tests ensuring quality and safety performance despite a reduction in the weight of the drums permitted optimisation and harmonisation of drum body thickness and widespread implementation. The practices, initially implemented in Europe with 80,000 units, were extended to an additional 122,859 units in other regions in 2025, resulting in an estimated total savings of more than 35 tonnes of steel.